Comprehensive Guide To Enrobing Conveyor Belt

Enrobing machines are one of the numerous sophisticated devices available to streamline production in the confectionery sector. You will learn everything about enrobing conveyor belts and its benefits. What is an Enrobing Conveyor Belt? The enrobing conveyor belt is a standard conveyor system in the food production industry, especially in the confectionery sector. It is made especially for enrobing, covering food with a layer of chocolate, icing, or other coatings to make chocolates, biscuits, or pastries. A continuous moving belt of food-grade materials, like plastic or stainless steel, is usually used as the enrobing conveyor belt. The belt passes through a reservoir or bath that holds the liquid coating ingredient. The food items to be coated are placed onto the moving belt, which takes them…

Enrobing machines are one of the numerous sophisticated devices available to streamline production in the confectionery sector. You will learn everything about enrobing conveyor belts and its benefits.

What is an Enrobing Conveyor Belt?

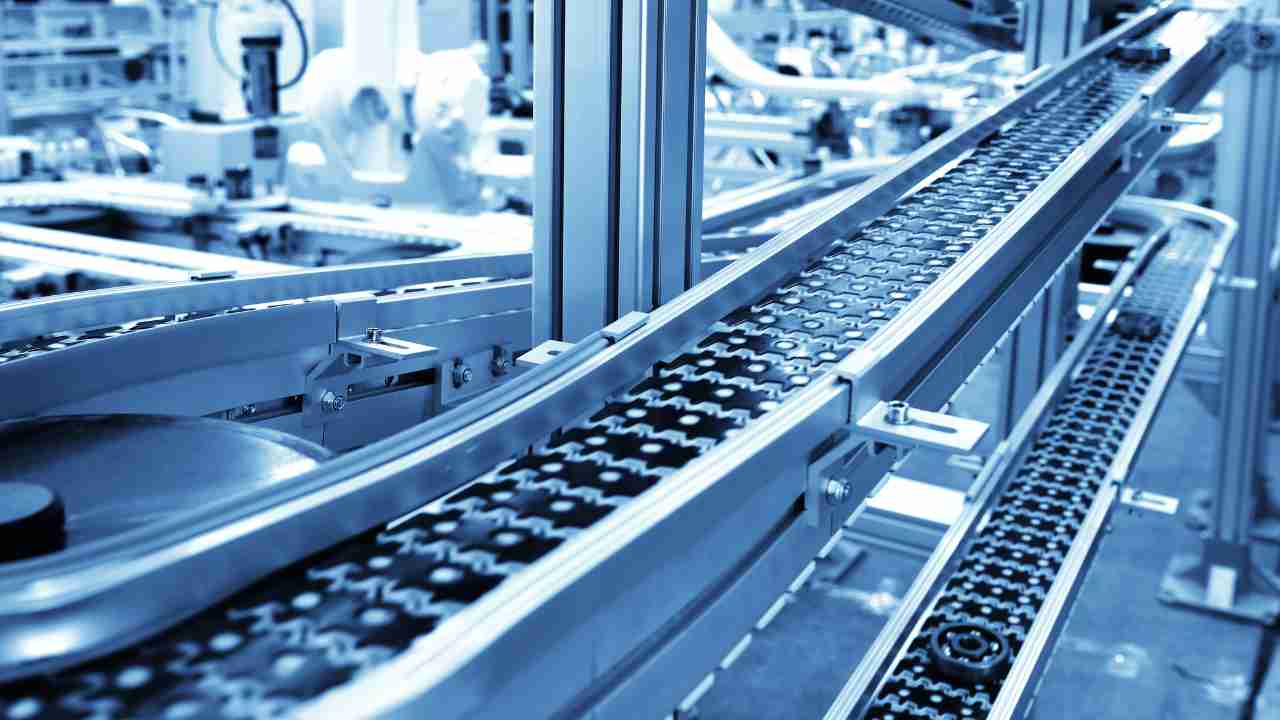

The enrobing conveyor belt is a standard conveyor system in the food production industry, especially in the confectionery sector. It is made especially for enrobing, covering food with a layer of chocolate, icing, or other coatings to make chocolates, biscuits, or pastries.

A continuous moving belt of food-grade materials, like plastic or stainless steel, is usually used as the enrobing conveyor belt. The belt passes through a reservoir or bath that holds the liquid coating ingredient. The food items to be coated are placed onto the moving belt, which takes them through the coating substance to ensure an even and uniform coating layer.

To guarantee that the appropriate coating thickness is reached, the extra coating material is typically scraped off as the food items go along the conveyor belt using a doctor blade or a set of rollers. The coated goods proceed to the following processing or packaging stage by moving along the conveyor belt.

Conveyor belt encasing is a crucial component in industrial production settings where uniformity in product quality and appearance is required for coating large quantities of food items efficiently and consistently.

What Are The Features Of The Enrobing Conveyor Belts?

Conveyor belts for enrobing are specialized pieces of machinery used in the food business, especially in the manufacturing of chocolate, to coat different foods in chocolate or other confectionery coatings. Conveyor belts with many characteristics are generally intended to enhance the efficiency and effectiveness of the enrobing process. The following are some typical characteristics:

Enrobing conveyor belts are constructed from food-grade materials like stainless steel or food-safe polymers to guarantee adherence to food safety standards and regulations.

To facilitate the easy movement of food products without compromising their texture or shape, flat wire belting surfaces are typically smooth. Conveyor belts with modular enrobing make it simple to disassemble and clean, which is essential for upholding hygienic requirements in settings where food is produced.

Conveyor belt encasings are made to be easily cleaned and maintained to reduce downtime and guarantee peak performance.

Manufacturers may provide conveyor belt enrobing choices to satisfy specific production needs or take into account special applications.

These characteristics work together to make enrobing conveyor belts in the food sector effective and dependable, assisting producers in continuously producing enrobed goods of the highest caliber.

Most enrobing conveyor belts feature speed settings that may be adjusted for precise control over the enrobing process and to handle varying production requirements.

Conveyor belts with encasing options can be purchased in various widths and lengths to fit a range of production configurations and food product sizes. Food items are moved through the enrobing process more smoothly and consistently when the conveyor belt’s tension is adjusted.

How Does an Enrobing Conveyor Belt Work

An enrobing conveyor belt is a vital aspect of enrobing equipment used in the food business, especially for making confections like chocolates, candies, and biscuits.

The general operation of an enrobing conveyor belt is as follows:

Feeding Zone: Food products to be coated are manually or automatically fed onto the conveyor belt at the start by an automated feeding system. These products could be anything from bars and almonds to biscuits and pastries.

Coating Bath: The food products pass under a reservoir or bath filled with the coating material—typically melted chocolate or icing—as the conveyor belt advances. This coating bath’s width and depth guarantee that the food items are adequately coated or completely submerged as they pass through.

Enrobing: The food products are fully or partially submerged in the coating material along the conveyor belt, guaranteeing a uniform and even coating on all sides. The layer’s thickness can be managed by varying the conveyor belt’s speed.

Drip Zone: The food products exit the coating bath and enter a drip zone once coated. The excess coating substance dripping off the food items back into the reservoir ensures a smooth and even coating free of the surplus building.

Cooling Tunnel (Optional): The cooling tunnel may be placed following the enrobing procedure in specific configurations. This tunnel ensures that the coating material sets appropriately and sticks to the food products by quickly cooling and solidifying them.

Discharge: Lastly, the coated food products come off the conveyor belt. Depending on the needs of the particular product, they may go on to further processing stages like packaging or additional decoration.

Discover why industry leaders trust Wire Belt for their enrobing conveyor needs. Explore new collections now to see how their solutions can drive your business forward.

Author Bio:

Twinkle Sharma As a content writer with 5 years of experience in writing and SEO, I have developed a deep understanding of creating compelling content that ranks well in search engines. Throughout my career, I have written for various industries, including technology, SaaS, healthcare, finance, and education.