Injection molding is a popular manufacturing technique for producing various parts and components. As a result, understanding the expenses of making an injection molded product is critical before selecting this procedure for your manufacturing operation.

This article investigates injection molding expenses. Understanding the factors that determine these expenses can assist you in estimating the costs of your injection molding project.

After reading this article, you can calculate the exact production expenses that injection molding will necessitate for your specific needs.

Let us get to the point and answer the question: how much does injection molding cost?

- Equipment Costs

For injection molding, numerous special-purpose equipment is required and utilized. This ranges from small desktop injection molding machines that businesses can use in-house to big industrial injection molding machines typically operated by service providers, contract manufacturers, and large manufacturers.

With smaller desktop injection molding machines and 3D-printed molds, producing low-volume products with injection molding is the most cost-effective. If you’re new to injection molding and want to try it out with a small investment, a tabletop manual injection molding machine like the Holipress or the Galomb Model-B100 would be a decent choice. Automated small-scale injection molding equipment, like the desktop machine Micromolder, are the best options for medium-series production of small parts.

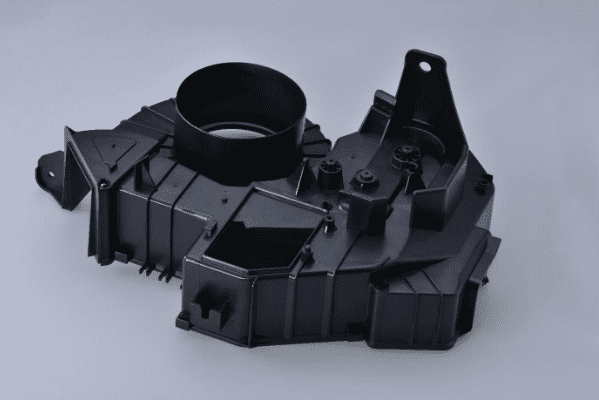

- Mold (Tooling) Costs

While the molding equipment is a one-time expense, the mold and mold base for the item is not. It is an expense for every part manufactured. As a result, tooling costs are one of the most critical driving forces for injection molding.

The injection molding costs vary depending on the procedure utilized to produce the molds. Three procedures are typically used for this purpose.

- CNC Machining

CNC machining is commonly used for metal molds. A stainless steel or aluminum mold would be standard. Cutting tools, for example, are used to remove material from an aluminum block when machining an aluminum mold. This type of machining produces aluminum molds with unrivaled precision.

The machine cycle for manufacturing molds is a minor disadvantage of CNC machining. These machines necessitate tooling setup and tool changes for different cut shapes.

- Electrical Discharge Machining

EDM stands for Electrical Discharge Machining. This method is used to make molds with complicated shapes. It is performed by applying electrical discharges to melt, bend, and shape the metal workpiece.

EDM, like CNC machining, is highly accurate. However, unlike CNC machining, which can be used on materials other than metals, EDM can only be used on metal molds.

- 3D Printing

3D printing is among the most time and cost-effective methods of producing injection molds. Because this procedure only requires a 3D printer, the cost is significantly lower. Additionally, there is no need for professional operators, which reduces labor costs.

- Injected Material

Depending on the requirements of the finished products, injection molding can employ a wide range of polymers such as ABS, PS, PE, PC, PP, or TPU.

The cost of obtaining mold materials varies depending on the material chosen. Thermoplastic pellets range in price from $1 to $5 per kg.

The material cost is determined by the model’s design, the material utilized, and the amount of material used to complete the injection molding process.

- Labor or Service Costs

Injection molding equipment is generally automated and relies on automation to complete the task. EDM machines, 3D printers, and CNC machines rely on CAD design parameters to create a mold. Also, automation is used in injection molding machines to inject ingredients into the mold, and industrial IM machines frequently cool and discharge the final item independently.

Labor costs take into account the following factors.

- Monitoring Costs

Despite the emphasis on automation, equipment operators are expected to oversee the injection molding process. Wages earned by operators during the process are added to the total cost of injection molding.

- Repair Cost

Repair and maintenance duties entail the replacement of faulty parts as well as the use of tools to carry out the maintenance process.

- Setup Cost

The setup labor focuses on the time required to configure the equipment used to create the mold and the end product.

Variables That Impact the Injection Mold Cost

- Part Features

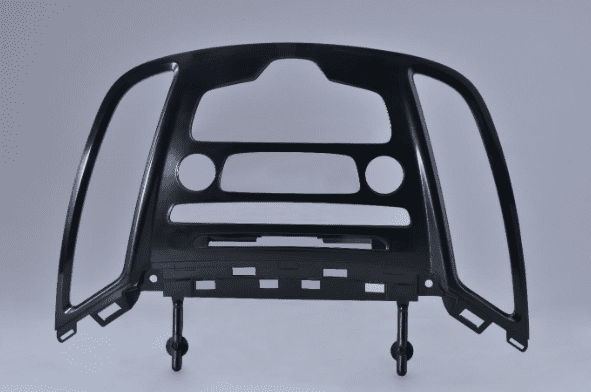

The injection mold cost is also affected by the final product’s attributes. Small components created by a separate injection molding process may be required if the product has complicated characteristics. Eliminating unneeded features at the design stage is one method of cutting costs.

- Part Variables

The cost is heavily influenced by the size and design of the part. Large injection molded products necessitate higher material prices as well as larger molds. On the other hand, complex designs may necessitate a multi-step molding procedure.

- Production Volume

You may have noticed that the manufacturing costs per part decrease when production is done in large quantities. The same concept applies to injection molding.

When you have a considerable manufacturing volume, you will need many molds to support it. However, the cost of the molds does not rise linearly. If the cost of a mold is $1 per part for 100 parts, the cost for 5000 parts can be around $0.5 per part, and the cost for 100,000 molds can be $0.25 per part.

Similarly, when production quantities increase, labor costs per part decrease. While the overall cost of production rises as production volumes increase, you will incur substantially reduced per-part costs.

Bottomline

Injection molding is now one of the most extensively used industrial methods. Every day, you see and touch various elements this method makes, such as bottle tops and plastic handles.

After reading this article, you should better understand how the price of plastic injection molding varies depending on the project.