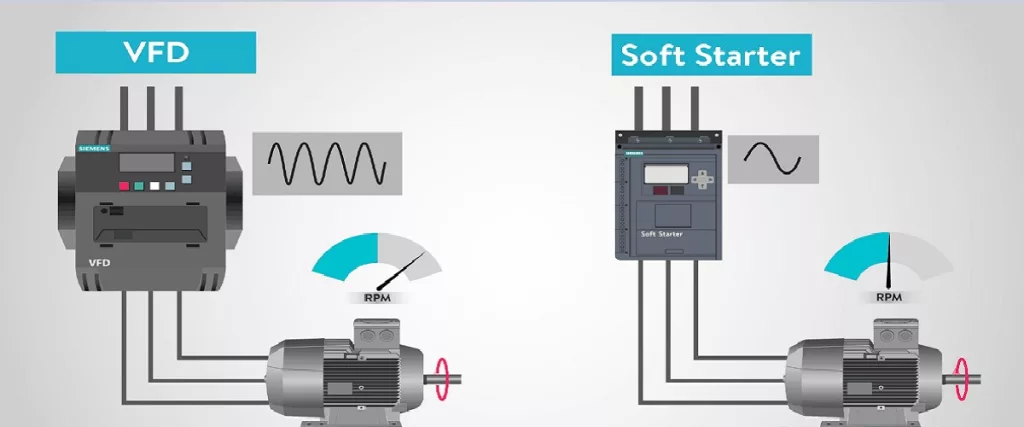

Soft starters and VFDs are two different types of ignition systems. A soft starter is an electrical device that causes the engine to start at a very low speed so that it doesn’t damage the carburetor, electrics, or engine parts as it starts. A VFD uses a magnetic rotary device rather than an electric motor for its starter motor, enabling it to control starting torque during cold start conditions more effectively.

Soft Starters

The roots of soft stalling can be traced back to the early days of automobiles when early cars operated by magneto ignition. The magneto is a coil of wire wrapped around a horseshoe-shaped piece of iron. As a current is passed through the coil, it produces an electromotive force that draws a small current from the battery. When this happens, the magneto creates a magnetic field around itself that attracts the horseshoe, which in turn generates large amounts of current, and the car starts to run.

The problem with this setup is when cold weather comes, all that heat has to go somewhere, so it is expelled into your engine, causing damage or, in some cases, not firing at all until you warm it up enough. The magneto is also in a very small housing, meaning it’s not protected from the weather.

A soft starter puts a large capacitor in between the battery and the motor, which rebuilds the current to the engine. This system allows a slow but steady warm-up of your car and keeps your motor protected. The capacitor acts as an electric fuel pump that allows less voltage to enter the system. A soft starter also doesn’t send high amounts of electrical current into your motor. This protects you and all your electrical equipment, such as lights, pumps, etc. The ways this is done are by using variable frequency drives, variable voltage drives, or variable speed drives like VFDs.

Soft starters are commonly used in a variety of industrial applications where motors are used, including pumps, fans, compressors, and conveyors. They are especially useful in applications where high inrush currents can cause damage to the motor or the load or where a smooth start-up is required to reduce mechanical stress.

Soft starters are typically less expensive than VFDs and can be simpler to install and maintain. However, they do not provide speed control, which may be a limitation for certain applications.

VFDs

Variable frequency drives (VFDs) are devices that are used to control the speed of an electric motor by varying the frequency of the power supplied to it. They work by converting the incoming AC power into DC power, then converting it back to AC power at a variable frequency and voltage.

VFDs provide precise speed control, making them ideal for applications such as conveyors, fans, and pumps that require variable speed operation. They can also be used to reduce energy consumption and increase motor efficiency by adjusting the motor speed to match the load.

VFDs allow for precise control of the motor speed and torque, and can be used to optimize the motor’s performance and energy efficiency. They are commonly used in applications where the load varies or where a constant speed is not required, such as HVAC systems, pumps, and fans.

In addition to speed control, VFDs also provide motor protection features such as overload protection, short circuit protection, and under/over voltage protection. This makes them suitable for a wide range of applications.

However, VFDs are typically more expensive than soft starters and can be more complex to install and maintain. They may also generate more electrical noise and require additional filtering and grounding measures.

Differences Between Soft Starters and VFDs

The main differences between soft starters and VFDs are:

Control Method

Soft starters control the acceleration of the motor by limiting the inrush current. In contrast, VFDs control the speed and torque of the motor by varying the frequency and voltage of the power supplied to the motor.

Motor Control

Soft starters only control the starting and stopping of the motor, while VFDs allow for precise motor speed and torque control.

Energy Efficiency

VFDs can improve the energy efficiency of the motor by adjusting the speed and torque to match the load, while soft starters do not affect the energy efficiency of the motor.

Cost

Soft starters are generally less expensive than VFDs, although this can vary depending on the specific application and requirements.

| Soft Starters | VFDs |

| Control method | Voltage control |

| Starting current | Reduced, typically up to 600% |

| Speed control | No |

| Motor protection | Overload protection only |

| Application | Suitable for applications with high starting torque, such as pumps and compressors |

| Cost | Lower |

Applications of Soft Starters and VFDs

Soft starters are commonly used in applications where high inrush currents can cause damage to the motor or the load or where a smooth start-up is required to reduce mechanical stress. They are commonly used in pumps, fans, compressors, and conveyors.

VFDs are commonly used in applications where the load varies or where a constant speed is not required, such as HVAC systems, pumps, and fans. They are also used in applications where precise motor speed and torque control is required, such as in manufacturing processes.

Conclusion

Both soft starters and VFDs have advantages and disadvantages, and the choice between them depends on the application’s specific requirements. Soft starters are a good choice for applications with high starting torque, while VFDs are better suited for applications that require variable speed control. Careful consideration of the application’s requirements, as well as the cost and maintenance factors, should be taken into account when selecting between the two.