When the automotive and consumer tech industries faced sudden disruptions in 2020 because of the computer chip shortage, everyone became aware of how a small thing like this can have a huge worldwide impact. The high demand for integrated circuits affected in some way a whopping total of 169 industries, not just consumer electronics and car manufacturing.

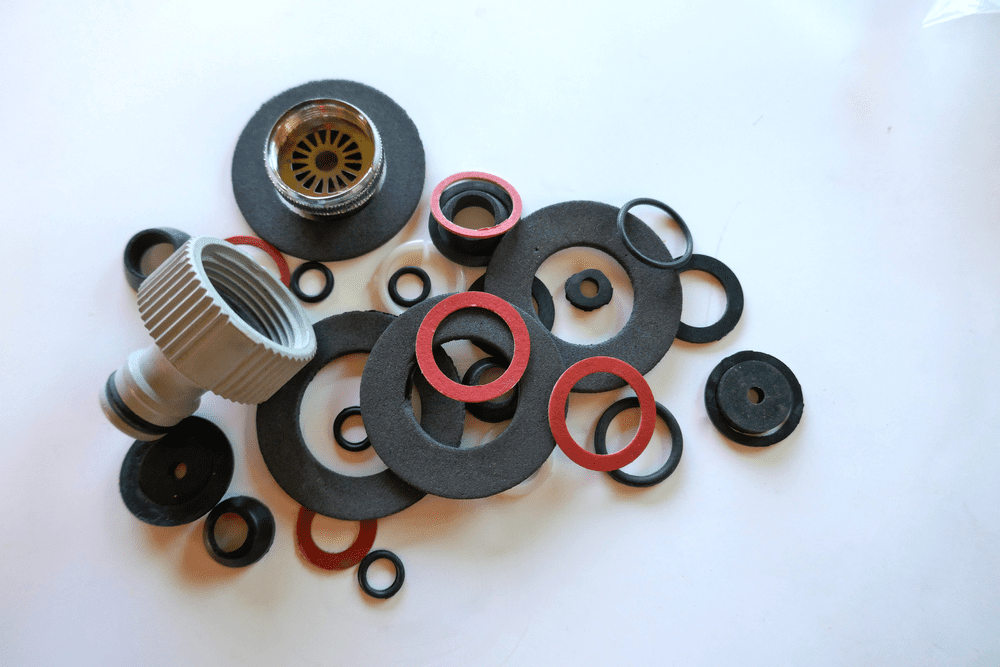

Computer chips are by no means the only components you need to pay attention to when it comes to global supply chain processes. Small plastic and rubber parts play a significant role — especially custom ones — due to the number of businesses that need them for product manufacturing or as part of their equipment. Let’s take the example of a small but essential rubber product: o-rings. While easy to overlook, they are everywhere, and stocking up on them is a good idea to avoid disruptions.

Why You Need High-Quality Rubber Seals

O-rings come in different sizes and materials and they are widely used in business equipment ranging from kitchen faucets in restaurants to MRI machines and space shuttles. The top industries that need to ensure a fully optimized supply chain in terms of rubber seals are aerospace and aviation, oil and gas, medical and pharmaceutical, automotive, food and beverage, water and refrigeration.

These particular industries have to choose a reliable manufacturer that carries a wide variety of inventory and custom or bulk ordering options that help optimize the supply chain to avoid disruptions. The right supplier will guide you and help you choose the appropriate sizes and materials that fulfill your business needs. They will also be able to provide you with custom parts in bulk, helping you cut costs without impacting product quality.

How an O-Ring Shortage Causes Disruptions

To better understand the risks of running out of o-rings, let’s first take a look at what their role is. In big strokes, o-rings are placed into a groove between two surfaces to ensure no liquid or gas can escape. This makes them indispensable in mechanical parts and processes, and a perfect seal must be ensured regardless of temperature or pressure. This is why different applications require different properties and materials.

Now, if the raw material necessary for the o-rings used in your equipment becomes scarce, as was the case of natural rubber during COVID-19 lockdown, then o-ring production can slow down significantly. It is then a joint effort of manufacturers and customers to ensure proper operation and avoid disruptions. What you as a customer can do is stock up on small essential parts, especially if you have custom requirements.

Bottom Line: Choose a Local Manufacturer

To make sure you benefit from the best supply chain possible, go for domestic manufacturing. This will translate into shorter lead times, high-quality products and reduced costs due to shorter transport distances. While outsourcing overseas can be tempting through the lens of apparently lower costs, the risks associated with far away companies could cripple your supply chain.

By choosing a manufacturer that can create molds and tooling locally, you will benefit from reduced reaction time, quicker manufacturing and reduced unforeseen costs. You will also have a consistently reliable supply of a wide range of complex and custom rubber components besides the standard o-rings.

Whether you are a global business professional or specialize in supply chain management, remember to put rubber seals on your watchlist and choose wisely who you partner with.