As a family-owned wholesale distributor of spices, De Silva Spices of Pico Rivera, Calif., imports about 90% of the nation’s cinnamon; founded in 2001, the 60-employee company is also a major importer of hibiscus, dried chiles, herbs, and Hispanic food products. In total, it handles about 200 different items at any given time. By selling its products mainly through multiple retail stores and via wholesale distribution channels, De Silva Spices’ reach expands to 30 different countries, most of which are located in Latin America.

As De Silva Spices began to grow and expand into new opportunities, the organization realized that they needed to move their production planning and forecasting from Excel into their ERP System (NetSuite), and to do so they were in need of a NetSuite consultant. They reached out to AlphaBOLD, their trusted advisor for help with the Material Requirements Planning (MRP) setup. AlphaBOLD’s reputation as a NetSuite solution provider helped De Silva Spices make an informed decision regarding their enterprise resourcing needs.

Find out more about MRP in NetSuite here.

Planning Challenges

In the context of planning, G.P. faces the following challenges:

Raw Material Sourcing

As the demand for spices grows, so does G.P.’s production. To avoid delays in production G.P. requires a solution that will accurately forecast the demand for raw material/ingredients (based on the finished goods demand) that the organization must procure for blending. This is becoming very difficult to do outside of the ERP system, as the number of SKU’s and related reports that must be extracted is constantly expanding.

Furthermore, G.P. categorizes their BOM components and would like to plan production and component purchases by each category. Doing this manually in Excel is becoming increasingly difficult.

Planning Difficulties

The production and the supply chain management team are sharing data that is often inaccurate and inconsistent. The data that is being extracted and manipulated by different teams often results in inaccurate projections. In a nutshell, the planners are neither aligned nor are they using the same tools.

Consequently, if there is an unplanned surge in demand, such as what is currently affecting the economy due to the COVID crisis, the planners do not have sufficient time to adjust as they use antiquated, external tools.

Manual Entries

Once the projections are finalized, Purchase Orders and related Work Orders are entered manually. With increasingly complicated and delayed delivery schedules, PO lines need to be separated and maintained manually by the planners. The transactional adjustments/updates that need to be made across the board are becoming increasingly labor-intensive and difficult to manage and support.

NetSuite Solution Provider

Let us walk through how AlphaBOLD and NetSuite MRP can assist G.P. De Silva with their product and process-related challenges. AlphaBOLD’s NetSuite support services offered G.P. De Silva the following:

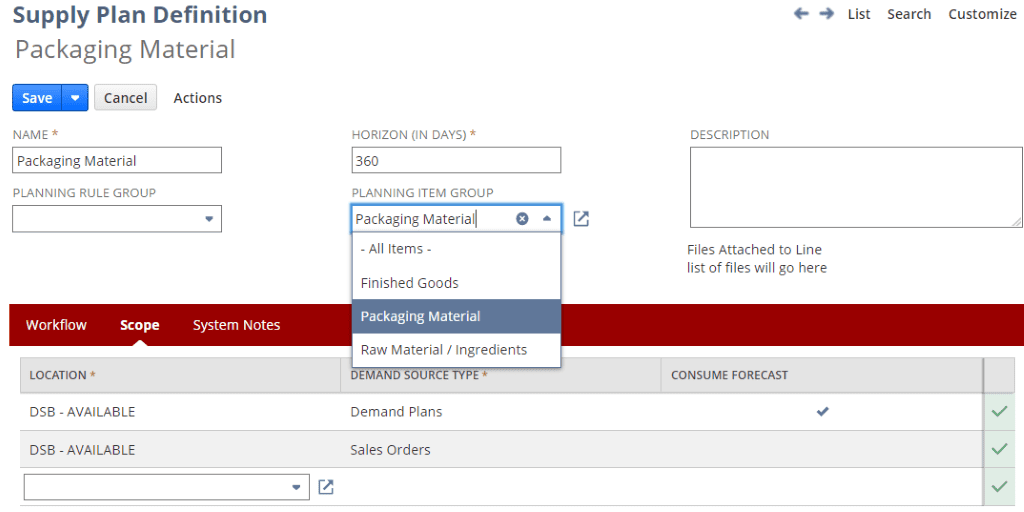

- Raw Material Planning by Item Category

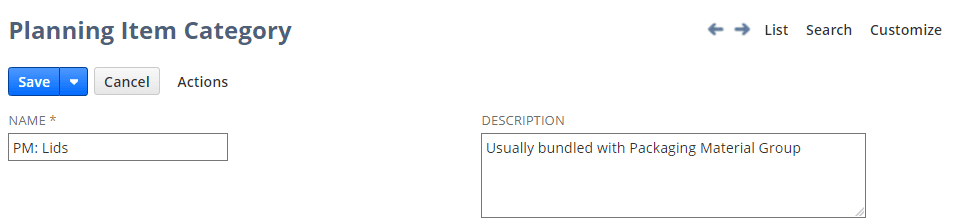

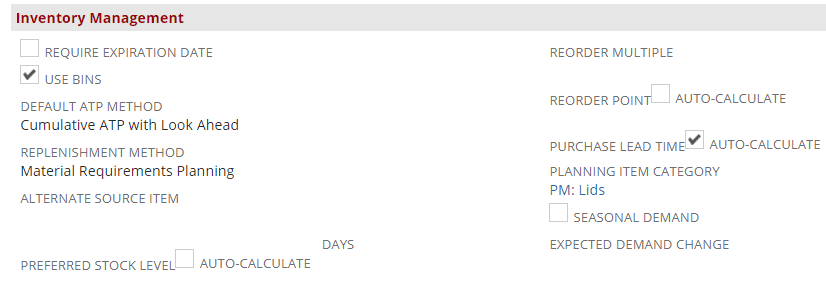

The Material Requirements Planning solution in NetSuite allows G.P. to tag its raw material components or finished products with specific ‘item planning categories.’ For example, lids, boxes, jars, etc.

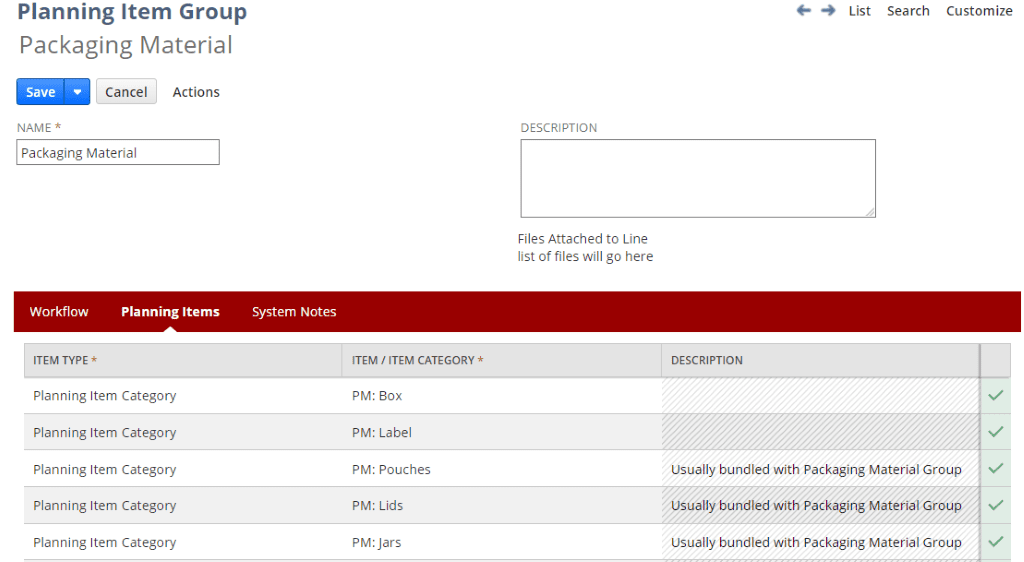

In the case of G.P. De Silva, the company would also like to group all these packaging categories into one single product group that would facilitate planning and procurement. This is accomplished through a ‘Planning Item Group’ element of NetSuite’s MRP.

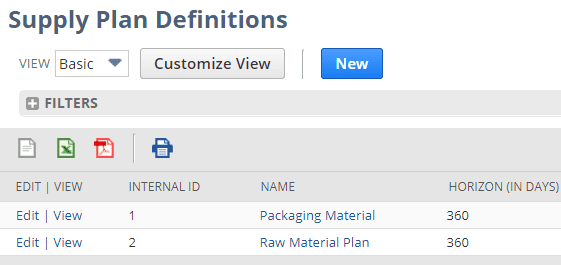

With these updates on the item, category, and group level G.P. can now create ‘Supply Plan Definitions,’ which define how the products (packaging material) will be sourced.

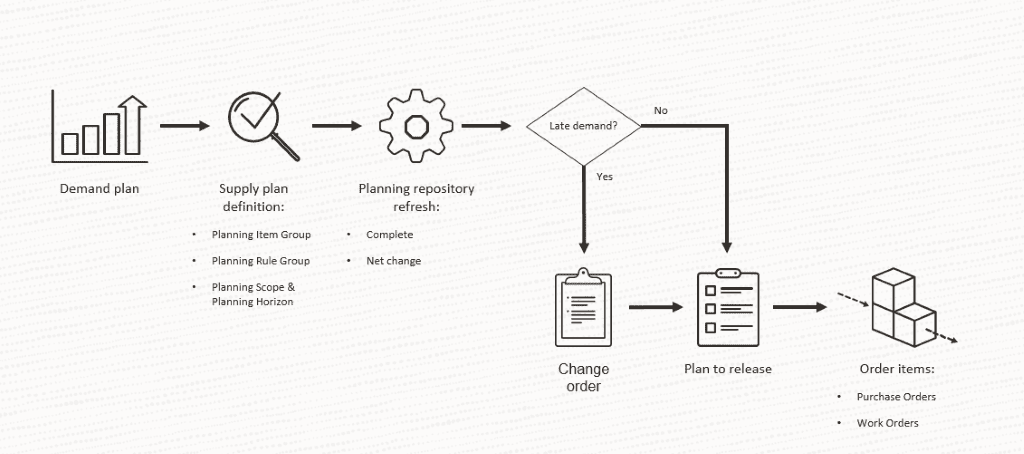

On the Supply Plan Definition page, we:

- Select the Planning Item Group

Group of item categories that we want to plan around.

- Set the planning horizon

Defines the planning scope or what future demand needs to be considered in the context of supply planning

- Define the demand scope

In this section, we specify the demand source (sales orders or demand plans), and we identify the locations/warehouses where to which the demand source is applicable

- MRP Work Bench

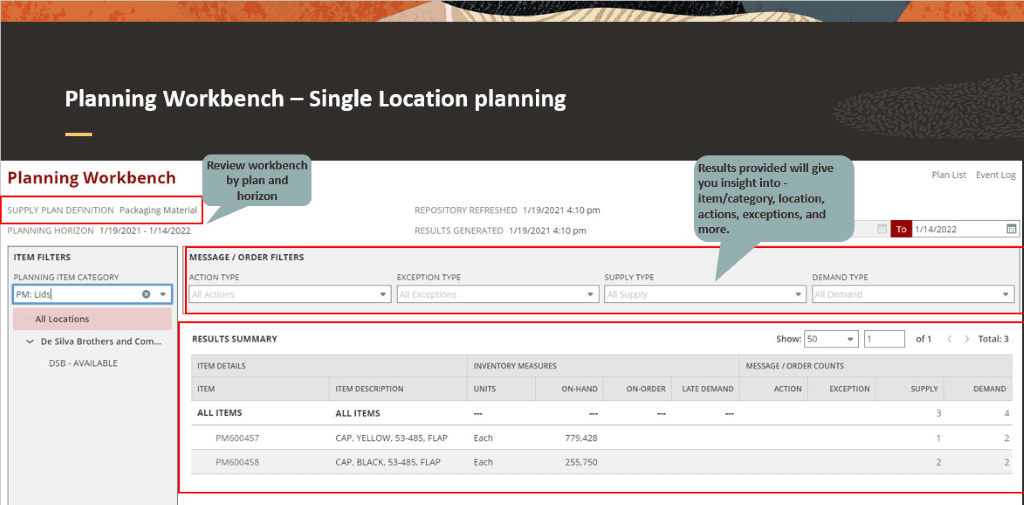

G.P. can now have multiple Supply Plans or Supply Plan Definitions that it can run independently. Each time the ‘Planning Repository’ is refreshed, it creates a workbench view that the planner can now use for purchase or production planning.

The planner can now filter the results by the planning item category to see only the system forecast or projections of interest to them. The Results summary pane shows action, exception, supply, and demand messages that the user can click through and review on one screen. This eliminates a need for complicated excel worksheets with countless tabs that often break.

- Planning Transactions

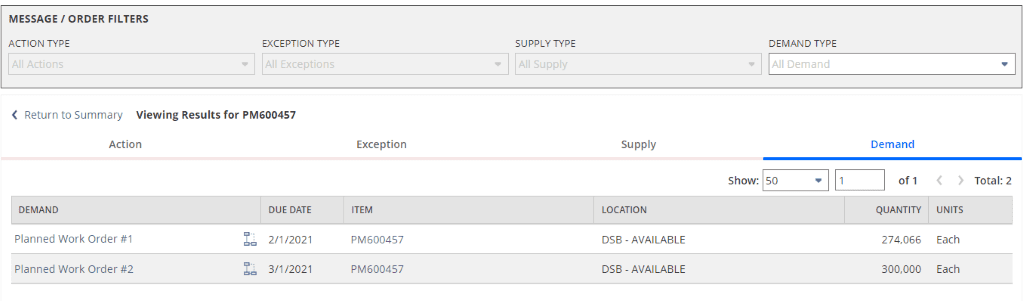

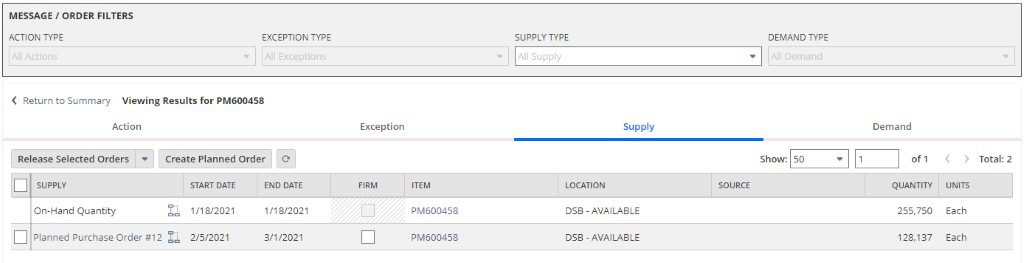

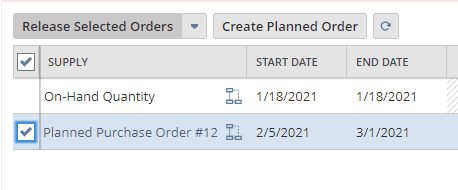

NetSuite MRP introduces the concept of planned orders. These are transactions that the system will recommend the planner creates based on supply planning projections based on a direct or indirect demand for G.P.’s products and related lead times (both purchasing and production). The system will show procurement suggestions for raw material.

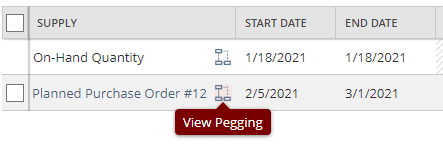

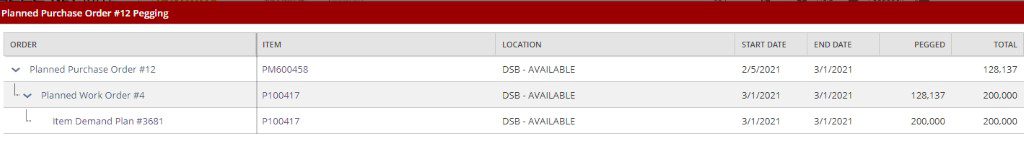

New ‘Pegging’ functionality allows the planners to see what drives the demand for raw material/ingredients.

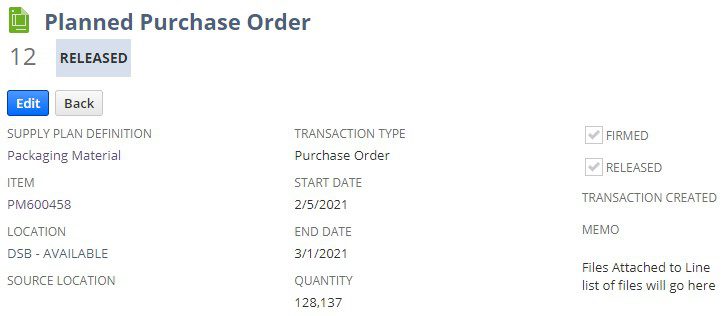

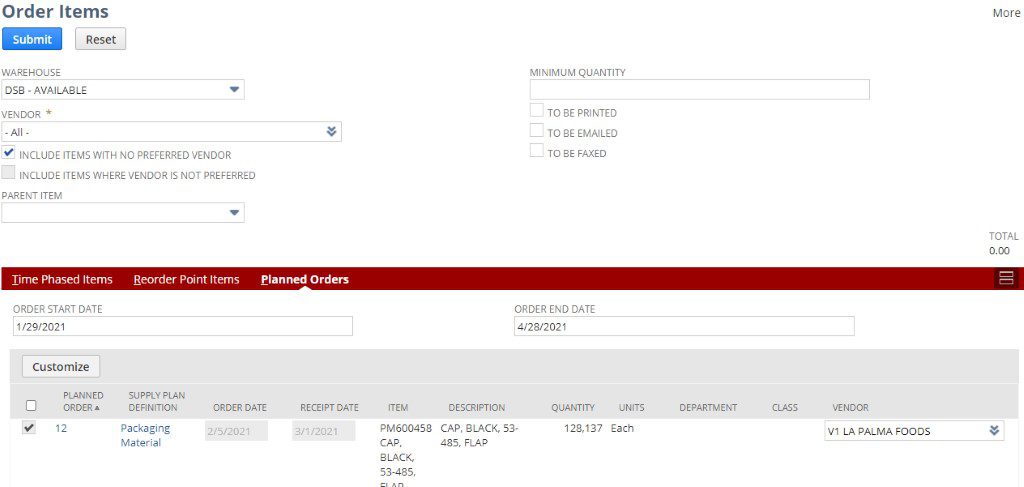

Once released, the planned Purchase Order will appear on the NetSuite standard ‘Order Items’ screen, which is constantly monitored by the Supply Channel Manager or the Procurement Specialist.

This process is streamlined, allows consolidation of multiple Planned Orders into a single Purchase Order, and eliminates manual entry, often resulting in errors.

To find out more about this solution and how it interacts with other functional areas of NetSuite EPR, including reporting, reach out to us for a free consultation and read more about AlphaBOLD’s NetSuite consultant services and ERP successes here.

About Author:

Ilija Budimir is a renowned Business Analyst, ERP Specialist, and Team Manager currently employed in AlphaBOLD as a NetSuite Practice Manager. He possesses a combination of business knowledge, IT technical skills, and consulting experience gained over the last 19 years in Canada, the U.S., and abroad. He has a track record of successfully completed ERP implementations, sales and marketing projects. Ilija supports constant innovation by applying the latest technologies and processes in day-to-day operations.